Application Success

VERTICAL TANK AGITATOR

Make: EKATO

Industry: Copper Mining

Challenge

Multiple agitators worked on floatation cells where they agitated a slurry mix to separate the copper minerals. The mine is in the middle of the desert with limited access to water. Due to this, the packing used to seal the vessel would last less than three months as there was no flush water available. This caused the stuffing boxes to leak minerals that were intended for processing. Seal failure led to production stoppage due to equipment downtime, safety risks from product leakage throughout the flotation cells, and loss of fine copper minerals which was costly to the mine.

Solution

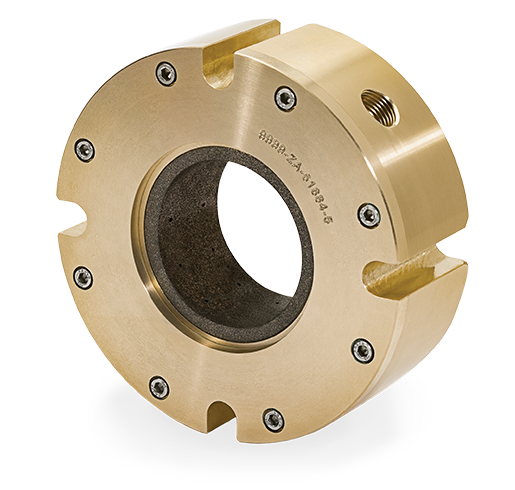

Split Inpro/Seal® Smooth Bore Air Mizer® shaft seals were installed on seven agitators. Air Mizer shaft seals us air to create a barrier on the shaft, permanently sealing against product leakage. Additionally, flush water was no longer needed for these applications. The designs were non-contacting, requiring zero maintenance, and fully articulated to accommodate shaft movement. A split adaptor plate was used to replace the gland packing stuffing boxes on each agitator.

Result

All seven seals were installed in 2023 and are currently running without issue, a drastic improvement from the previous three-month MTBF from packing.

Maintenance-Free Shaft Sealing

Inpro/Seal Air Mizer shaft seals provide permanent protection against product loss and contamination on industrial process equipment. With a unique, non-wearing design, Air Mizer seals are maintenance-free and constructed to last the lifetime of your equipment.

Ready to Get Started?

Count on us to improve reliability and process efficiency within your facility. Our experienced sales and engineering team can design custom engineered bearing protection or shaft sealing solutions to fit the exact requirements of your equipment and operating environment.