Application Success

VERTICAL FDA AGITATOR

Make: DCI

Industry: Food & Beverage

Challenge

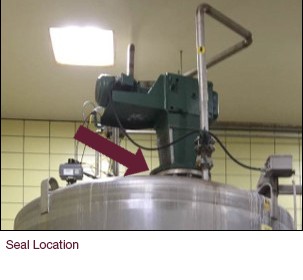

A US beer manufacturing facility produces 11,000,000 barrels of beer a year. They have five top-mounted yeast brink agitators that each have an 80 barrel capacity. These agitators have been causing issues for multiple years due to leaking packing. When the packing failed, contaminants entered the vessel, contaminating the product, and foam leaked out of the top of the agitator, creating a safety concern.

Solution

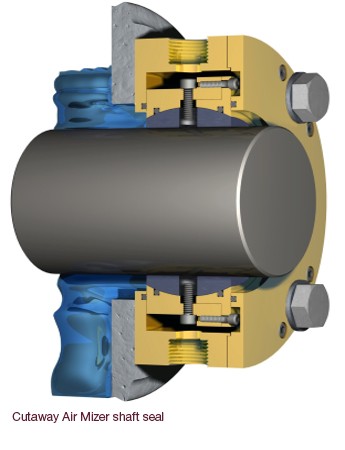

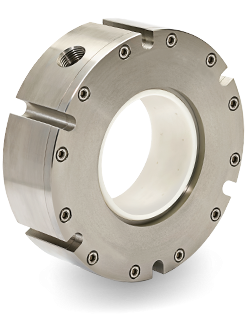

The customer turned to Inpro/Seal® and agreed to run a six month trial that started in April 2017. They installed an Inpro/Seal Food Grade Air Mizer® shaft seal on a single agitator. The Inpro/Seal Air Mizer seal is a non-contacting shaft seal that articulates to accommodate shaft angularity and can handle 0.250” of radial movement and infinite axial movement.

The seal was tested by thoroughly cleaning the vessel after each batch and taking ATP swabs inside and outside the vessel to verify no contaminants entered through the seal. The Air Mizer seal passed each inspection, which was a major breakthrough as packing never passed this test. Eliminating product contamination reduced the amount of times the facility cleaned the yeast brinks, significantly saving on maintenance costs.

Result

After installation of the first seal in April 2017, the remaining four agitators were upgraded with Air Mizer shaft seals in January 2018. All five agitators have run issue-free since installation.

Maintenance-Free Shaft Sealing

Inpro/Seal Air Mizer shaft seals provide permanent protection against product loss and contamination on industrial process equipment. With a unique, non-wearing design, Air Mizer seals are maintenance-free and constructed to last the lifetime of your equipment.

Ready to Get Started?

Count on us to improve reliability and process efficiency within your facility. Our experienced sales and engineering team can design custom engineered bearing protection or shaft sealing solutions to fit the exact requirements of your equipment and operating environment.