Application Success

DRY MOTOR SUBMERSIBLE PUMP

Make: Kishor Pump

Model: ASTRA Series

Industry: Wastewater Treatment

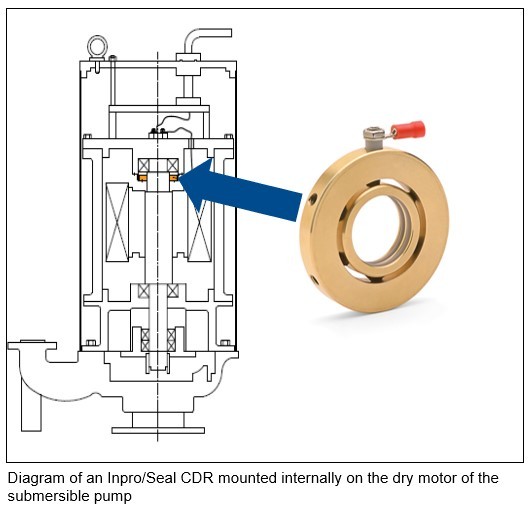

Challenge

Dry motor submersible pumps use a robust shaft and bearing design to limit shaft deflection from harsh pumping conditions, including solids. A VFD-driven dry motor submersible pump at a wastewater treatment center was experiencing premature bearing failure due to EDM machining from stray shaft currents. The bearing failures reduced the “stiffness” of the shaft assembly and lead to reduced mechanical seal life and excessive wear to the pump wet end, along with unpredictable reliability and constant removal and replacement of the bearings and seals.

Solution

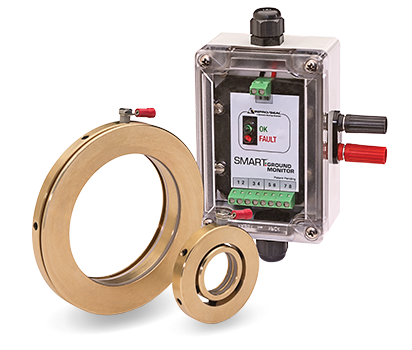

An Inpro/Seal® CDR® (Current Diverter Ring) was installed inside the motor to mitigate stray shaft currents. The CDR is constructed of solid corrosion resistant and highly conductive bronze and utilizes proprietary carbon filaments around the ring to divert the harmful stray shaft currents away from the bearings to the ground – preventing bearing damage.

Result

Inpro/Seal CDR shaft grounding solutions were installed on 25 submersible pumps in 2016. After proving effective against stray shaft currents, an additional 50 CDR units were installed. The CDR units have performed as expected, with zero maintenance requirements since installation.

Proven Shaft Grounding Technology

Inpro/Seal Shaft Grounding provides extensive protection against harmful stray shaft currents and contamination ingress to keep your VFD-driven motors, and coupled equipment, running. Inpro/Seal Shaft Grounding maximizes equipment reliability, reduces costly maintenance and minimizes unscheduled downtime.

Ready to Get Started?

Count on us to improve reliability and process efficiency within your facility. Our experienced sales and engineering team can design custom engineered bearing protection or shaft sealing solutions to fit the exact requirements of your equipment and operating environment.