Application Success

PANCAKE MIXER

Make: Bepex

Industry: Food & Beverage

Challenge

A large food manufacturer had 10 horizontal mixers that were each processing 15,000 lbs. of pancake mix every hour. Each mixer had six CO2 lines for cooling the hot oil that enters the mixer as well as preventing the chocolate chips from melting.

The mixers were fitted with contact seals that required repair kits every six months. The contact seals were not able to handle shaft articulation from the shaft-to-bore misalignment. Over a short time, wear on the seal faces caused a gap that allowed product leakage.

These failures added up quickly. Three times a day, plant personnel spent 20 minutes cleaning up the leaked pancake mix that accounted for 166 lbs. of lost product per day! Every six months, a two-person team spent eight hours replacing the seal faces at a cost of $6,000 per seal.

Solution

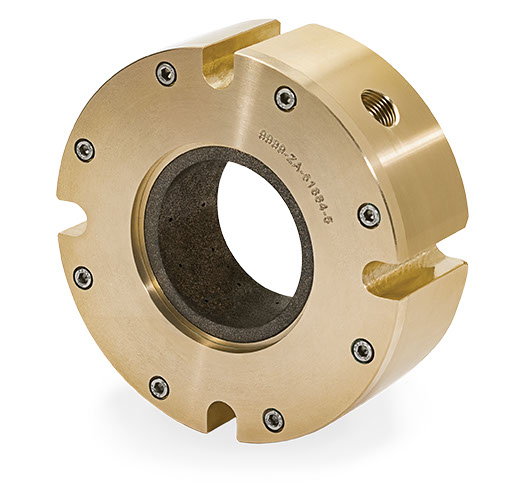

Split Inpro/Seal® Food Grade Air Mizer® shaft seals were installed. The Inpro/Seal Air Mizer seal is a non-contacting shaft seal that utilizes a positive air purge to permanently seal against product loss. Its unique design fully articulates to handle 0.250” radial movement and infinite axial movement.

Result

Between 2014 and 2016 all 10 horizontal mixers were retrofitted with Inpro/Seal Air Mizer shaft seals, saving the plant over $180,000 per year.

Maintenance-Free Shaft Sealing

Inpro/Seal Air Mizer shaft seals provide permanent protection against product loss and contamination on industrial process equipment. With a unique, non-wearing design, Air Mizer seals are maintenance-free and constructed to last the lifetime of your equipment.

Ready to Get Started?

Count on us to improve reliability and process efficiency within your facility. Our experienced sales and engineering team can design custom engineered bearing protection or shaft sealing solutions to fit the exact requirements of your equipment and operating environment.