Application Success

BLACK LIQUOR AGITATOR

Make: SPX/Lightning

Industry: Pulp & Paper

Challenge

Environmental regulations require companies involved in pulp and paper processing to monitor for leaking vapors and report leakage rates to the EPA every month. At a large pulp and paper mill, operators had to constantly adjust the agitator’s mechanical packing and regularly repack the stuffing box to eliminate vapors from the black liquor waste product that was leaking from the tank. This process led to high maintenance costs, harmful emissions, and environmental contamination risks.

Solution

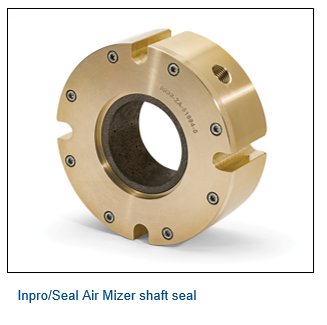

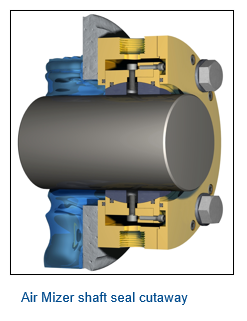

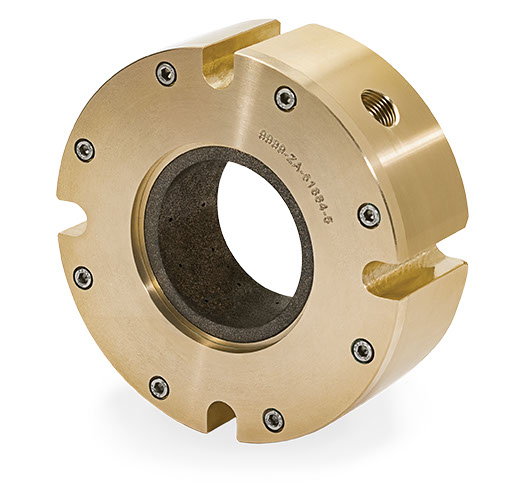

Inpro/Seal® collaborated with the customer to understand their unique operating requirements and recommended Air Mizer® shaft seals. These fully articulating, non-contacting shaft seals are maintenance-free and constructed to last the lifetime of the equipment. The installation process was completed in June 2021.

Result

The Inpro/Seal Air Mizers completely sealed the shaft and prevented leaking vapors immediately upon startup. The seals have been operating leak-free and trouble-free for 11 months, and the process area has not been cited for a violation or action has not been reported since the installation.

Maintenance-Free Shaft Sealing

Inpro/Seal Air Mizer shaft seals provide permanent protection against product loss and contamination on industrial process equipment. With a unique, non-wearing design, Air Mizer seals are maintenance-free and constructed to last the lifetime of your equipment.

Ready to Get Started?

Count on us to improve reliability and process efficiency within your facility. Our experienced sales and engineering team can design custom engineered bearing protection or shaft sealing solutions to fit the exact requirements of your equipment and operating environment.