Sleeve Bearing Motor Protection

Improve Operational Excellence and Profits

A Unique Sealing Challenge

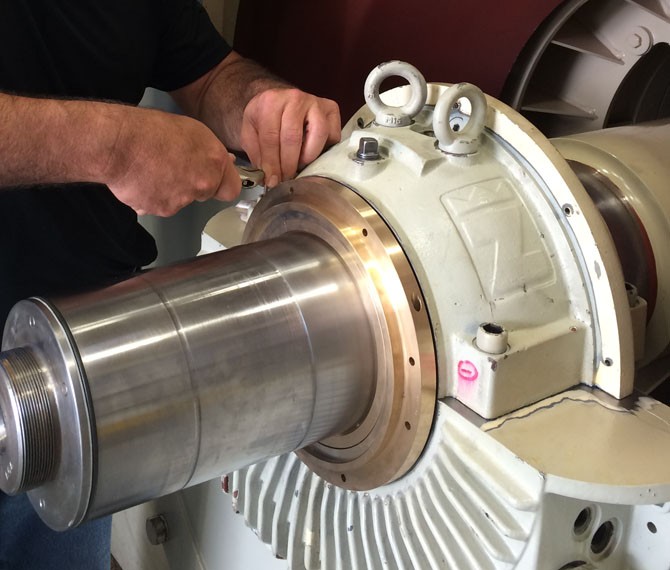

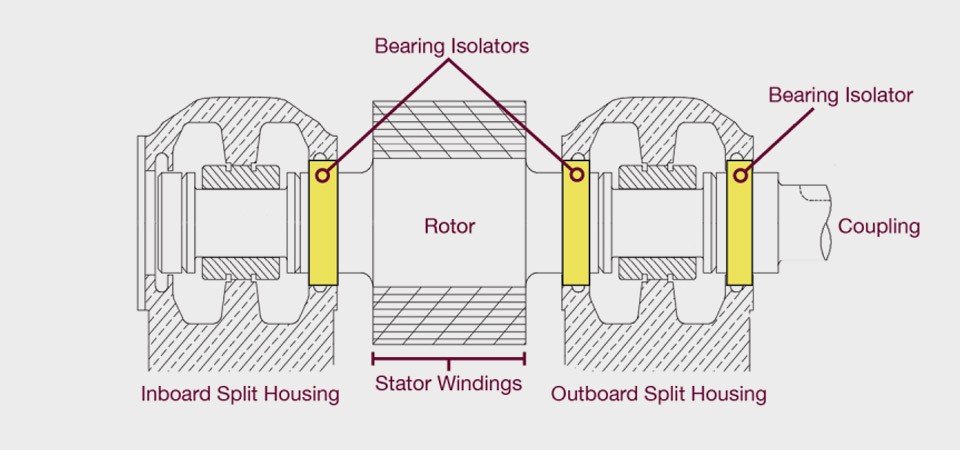

Sleeve bearing motors are a critical asset in any industrial operation. Unfortunately, they suffer from unique environmental and operational challenges that make them difficult to seal. Ineffective internal labyrinth seals allow oil to be drawn into the motor windings, coating them, degrading the insulation and causing them to overheat. Ineffective labyrinth seals on the drive end allow contamination to enter the bearing housing. Both conditions lead to unscheduled downtime, expensive repair and safety issues.

A Permanent Sealing Solution

Effectively seal your bearing housing with Inpro/Seal Bearing Isolators. The Inpro/Seal SBM Bearing Isolator design, designed specifically for sleeve bearing motors, permanently protects the windings from oil contamination and the bearings from external contamination.

The innovative design uses a unitized rotor to expel lubricant back to the bearing sump and away from the windings, while also accommodating shaft rise and axial movement during startup and shutdown.

The SBM Bearing Isolator is custom engineered using multiple features, like mounting configuration, o-ring crush and split construction, to design the precise seal for your equipment and operating environment.

Facts at a Glance

Inpro/Seal Bearing Isolators on sleeve bearing motors:

- Permanently protect motor winding and bearings

- Accommodate axial movement and shaft rise

- Can be split for ease of installation

- Are maintenance free

- Are a direct retrofit, with no need for housing modifications on most motors

- Can be designed with an air purge for 2-pole motors

- Are backed by our best-in-class performance guarantee

Increase Reliability. Decrease Costs.

Inpro/Seal increases reliability and enhances performance on rotating equipment across multiple industries with permanent bearing protection and complete shaft seals. Read more about our innovative technologies or the industries we serve.

Ready to Get Started?

Count on us to improve sleeve bearing motor reliability through permanent bearing protection. With over 40 years of experience, we are the trusted source of Bearing Isolator technology.