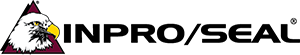

Pillow Block Bearing Protection

Increase Pillow Block Reliability and Cost Savings

The Importance of Bearing Protection

Pillow blocks are an important component to the rotating process as they support the shaft on a variety of rotating and power transmission equipment. They are designed to operate many years, yet they consistently cause downtime due to bearing failure from contamination ingress or lubrication loss.

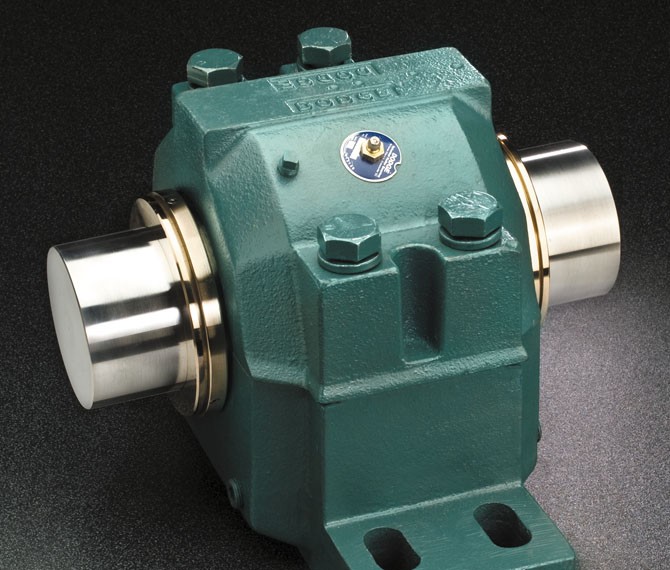

Ineffective Seals Lead to Downtime

Pillow blocks commonly use LER or LOR rings to seal the bearings. These simple gap seals rely on a tight clearance between the seal and shaft as the sealing mechanism. Dirt and water particulates can easily pass through the seal, contaminating the bearings along with allowing lubrication to escape to atmosphere.

In some instances, grease is used to purge the seal, creating a barrier. Grease purged seals are labor intensive and unreliable as the seals need to be constantly greased or else become ineffective in a short time.

Increase pillow block reliability and mean time between repair (MTBR) with permanent bearing protection.

A Permanent Sealing Solution

The Inpro/Seal Bearing Isolator increases pillow block reliability with permanent bearing protection against contamination ingress and lubrication loss, significantly increasing mean time between repair (MTBR) and decreasing maintenance costs. The unique non-contacting design has no wearing parts, lasting the lifetime of your equipment.

Bearing Isolator Design for Pillow Blocks

Facts at a Glance

Inpro/Seal Bearing Isolators installed on pillow blocks:

- Are IP66 rated, protecting against contamination ingress from heavy water spray and dust

- Are designed for both grease and oil

- Extend pillow block MTBR

- Are non-contacting, eliminating extra drag on the shaft

- Are non-wearing and maintenance free

- Are designed to fit exactly into your existing pillow block design

- Are backed by our best-in-class performance guarantee

Same-Day Shipments

Inpro/Seal is committed to making sure you have the right technology, right when you need it. We know that time is money. That’s why we offer same-day shipments on most Bearing Isolators, even new and custom designs. If you require same-day shipments on an Inpro/Seal Bearing Isolator, contact your local Inpro/Seal Representative.

Increase Reliability. Decrease Costs.

Inpro/Seal increases reliability and enhances performance on rotating equipment across multiple industries with permanent bearing protection and complete shaft seals. Read more about our innovative technologies or the industries we serve.

Ready to Get Started?

Count on us to improve pillow block reliability through permanent bearing protection. With over 40 years of experience, we are the trusted source of Bearing Isolator technology.